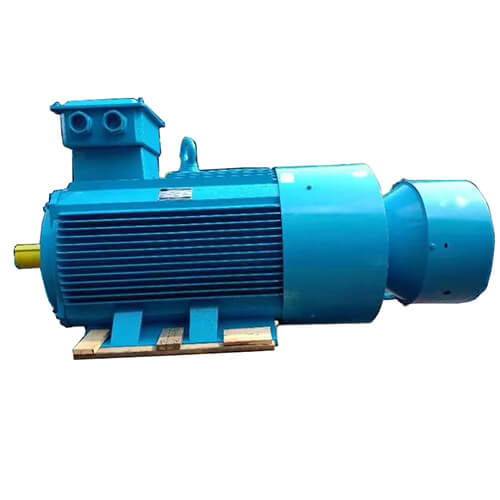

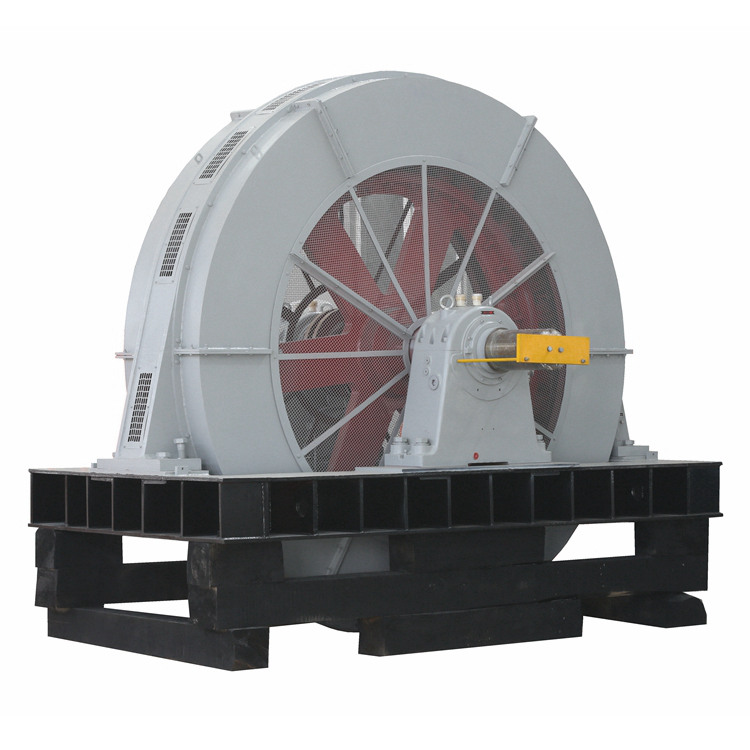

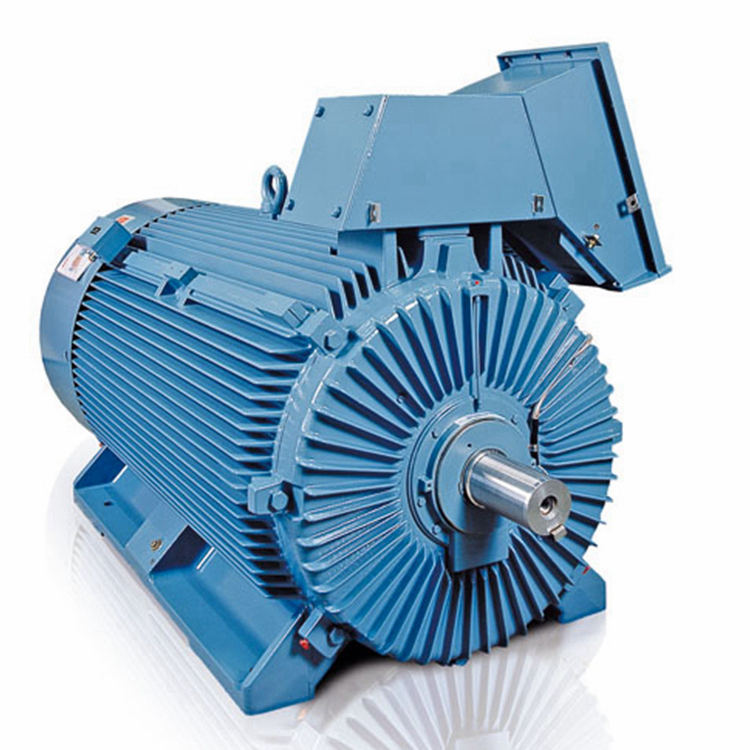

The JR series motor is a protective winding type rotor three-phase asynchronous motor with cooling method IC01 and continuous working system (S1). This series of motors can provide a large starting torque at a small starting current and can adjust the speed within a certain range.

The JR winding slip ring motor casing is a cast iron casing or a steel plate welded casing with high structural strength and good mechanical properties. The motor shaft extension end and the non-bearing end have an inlet and outlet air outlet, and the motor slip ring is located at the non-bearing end. The series of motors have simple structure, convenient installation, convenient maintenance, large starting torque and safe and reliable operation. JR winding slip ring motors can drive a variety of different machines, such as fans, compressors, pumps, crushers, ball mills, winches, hoists, transport machinery and other equipment, as well as mines, machinery, power plants and Used as prime mover in various industrial and mining enterprises.

The JR series motor is a wound rotor three-phase asynchronous motor. This series of motors meets the technical standard conditions. It can drive a variety of different machines, such as fans, compressors, pumps, crushers, ball mills, cutting machines, transport machinery and other equipment. It is used as a prime mover in the machinery industry, power plants and various industrial and mining enterprises. The rating of the JR winding slip ring motor is based on the continuous working system (S1). The frequency is 50HZ, the rated voltage is 220V/380V, 380V, 415V, 3000V, 6000V, which can be designed to 3300V/10000V according to the needs of users.

The protection of this series of motors is IP23; the cooling method is IC01; the structure and installation method of the motor is generally IMB3, and it can also be designed as vertical installation according to customer requirements.

The ratio of the maximum torque to the rated torque of the JR winding slip ring motor at rated voltage is not less than 1.8.

The JR winding slip ring motor must be connected to the starting varistor in the rotor circuit at the start. It is not permissible to short-circuit the rotor windings directly.

Product Parameters

Motor power range: 80KW-850KW

Rated voltage: 380V/415V/660V/690V/3000V/33000V/6000V/10000V

Number of poles: 6/8/10/12

Rated frequency: 50Hz/60Hz

Protection level: IP23

Cooling method: IC01

Working system: S1

Insulation class: B

Wiring method: △

Ambient temperature: ≥ -15 ° C and ≤ 40 ° C

The JR winding slip ring motor is suitable for altitudes up to 1000 m and ambient air temperature is 0-40 degrees. The protective motor should be installed in a room with clean air, no dust, steam, acid, alkali and other corrosive gases. It is not allowed to be used in an environment containing explosive gas or dust.

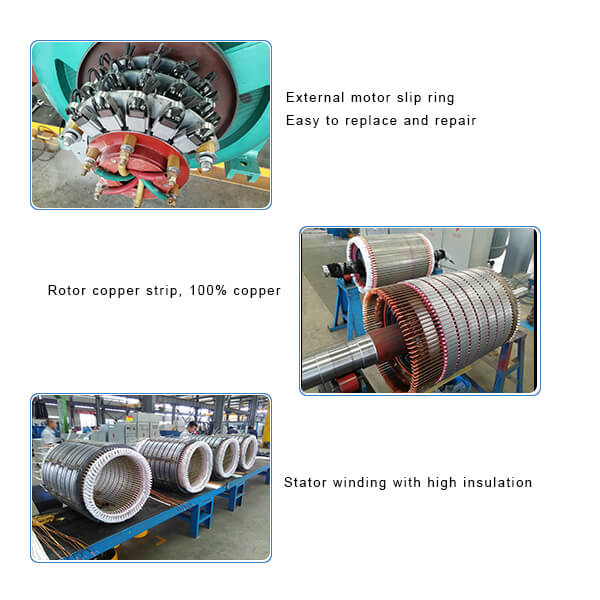

Feature of Product

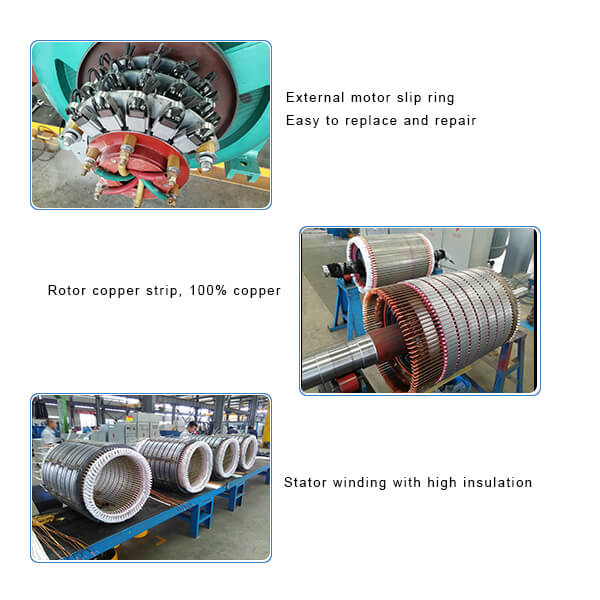

The JR winding slip ring motor casing is a cast iron casing or a steel plate welded casing with high structural strength and good mechanical properties. The motor shaft extension end and the non-bearing end have an inlet and outlet air outlet, and the motor slip ring is located at the non-bearing end. The series of motors have simple structure, convenient installation, convenient maintenance, large starting torque and safe and reliable operation.

Packing and Shipping

1. The outer packaging of the products are all standard export-oriented wooden plywood packaging.

2. the product packaging is protected by moisture, water plastic soft packaging

3. For products with special transportation requirements (such as temperature, fragile, variability, and easy to get wet), the packaging protection measures will be strengthened, and the target mark will be printed on the package.

4. There are obvious signs and symbols on the packing box that must be paid attention to during transportation and storage (such as position, moisture, rain, shockproof, lifting position, etc.).

Equipment Capacity

The company has large-scale laboratory, intelligent CNC winding machine, CNC rising machine, automatic wrapping machine, VPI high pressure vacuum immersion system, large-scale dipping paint drying furnace, 60 tons test platform, large vertical car, milling machine, grinding machine, Each type of dynamic balancing machine, double-feedback test and detection system with 6MW (12MW) motor and other motor production professional equipment more than 500 sets, sound mechanical equipment processing capacity, to lay a good foundation for customers to improve good quality motor products.

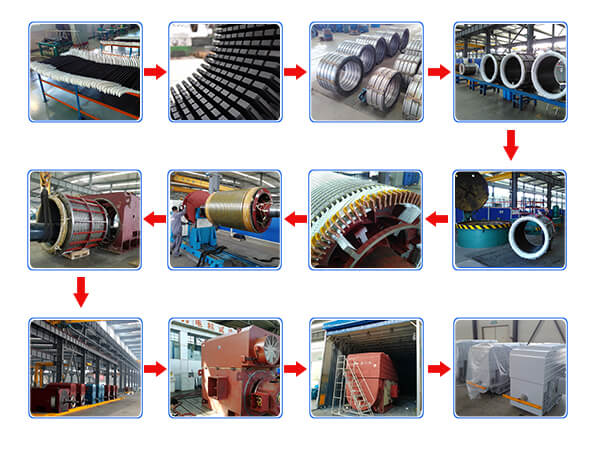

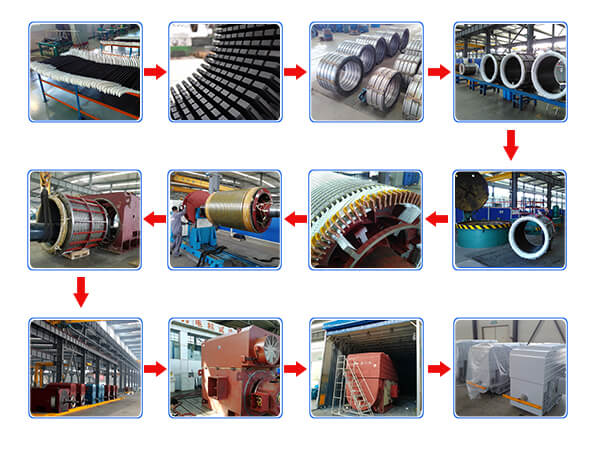

Main Process Flow of the Motor

Motor stator: casing processing → punching press → iron core seating → coil making → weaving → dipping paint drying

Electronic rotor: blank shaft processing → iron core press installation → iron core cast aluminum → rotor string shaft → weave → dipping paint drying → dynamic balance

Motor assembly: stator rotor assembly → machine test → motor appearance coloring →packaging storage

Why Choose Us

1. Professional motor manufacturing service provider;

2. Sound product quality management and certification system;

3. Have a professional sales and technical service team;

4. The motor has perfect process and strong mechanical processing capability;

5. High standard product technical service system;

6. good faith and mutual benefit, good credit guarantee.