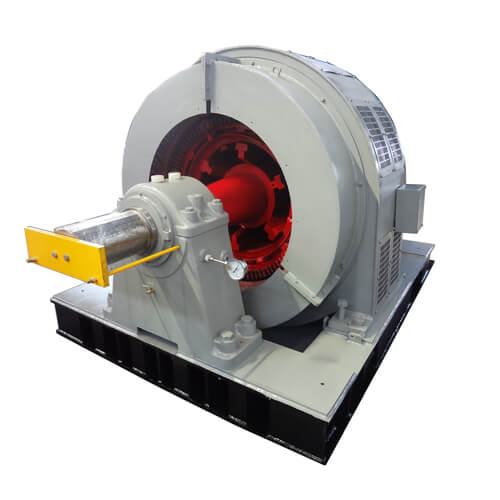

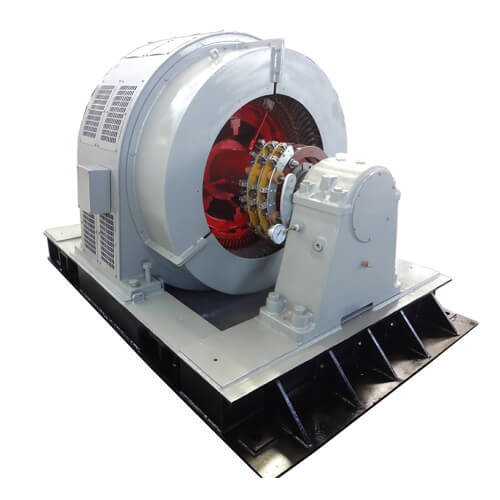

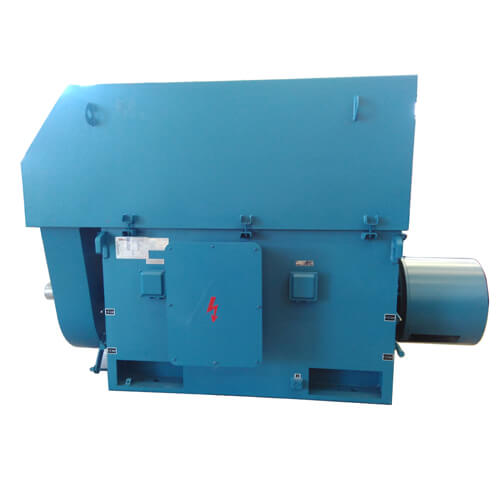

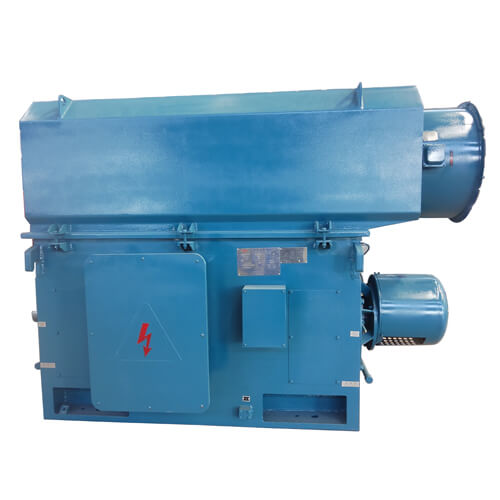

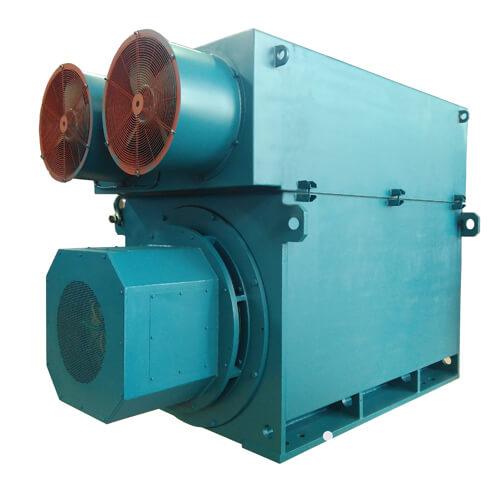

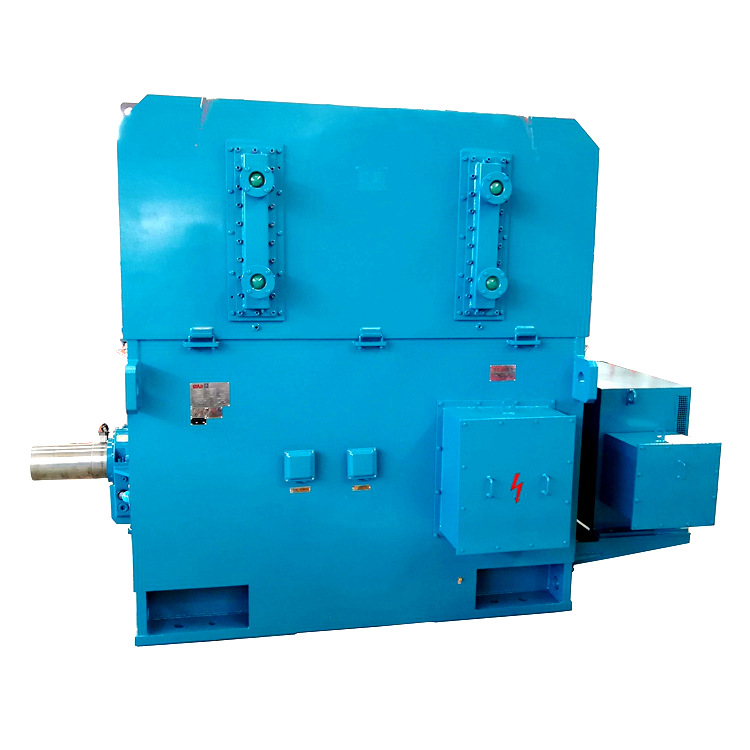

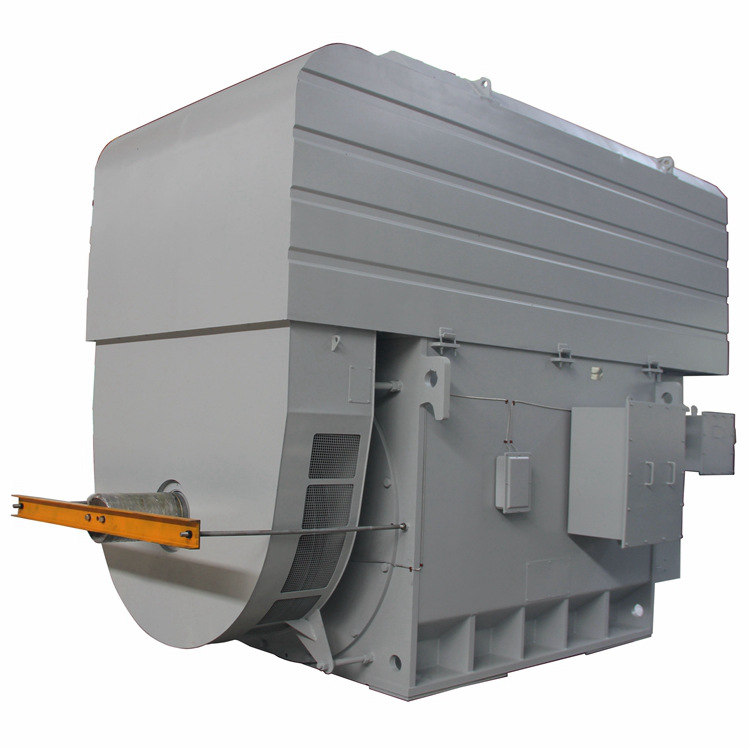

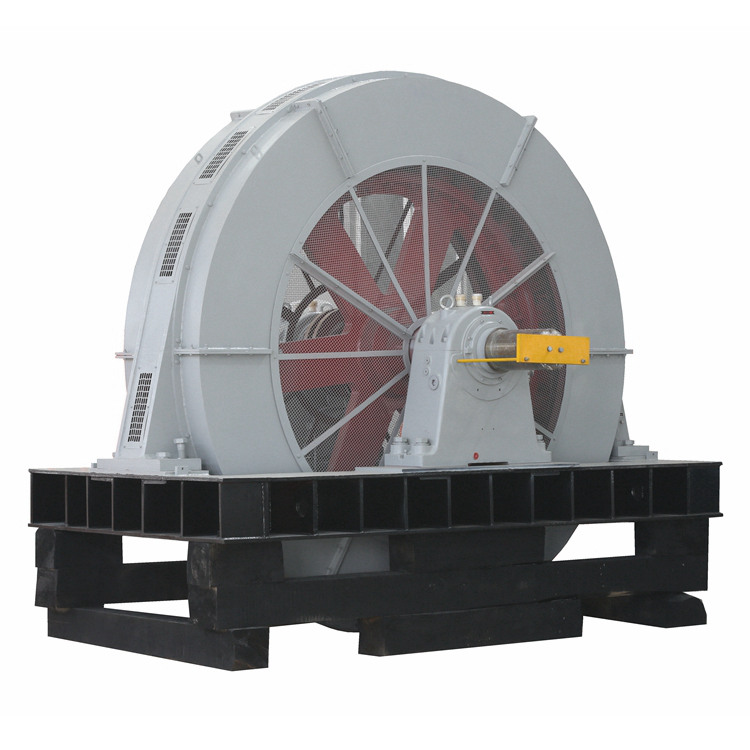

YR series heavy-duty high-voltage slip ring motor (open type) is a steel plate welding machine base, horizontal structure large-winding three-phase asynchronous motor. The modified model has the advantages of high efficiency, strong overload capability, low noise, small vibration, reliable structure and beautiful appearance, and is suitable for supporting imported equipment.

YR series heavy duty high voltage slip ring motors (open type) are manufactured in accordance with IEC standards. This series of motors is an upgraded product of JR series large-scale wound rotor motor. It uses advanced production technology and has been carefully designed to make the main performance indexes of this series of motors excellent. YR series large slip ring motor can be used as the prime mover of rolling mill, hoist, water pump, compressor, ball mill and other mechanical equipment. It is suitable for places with small capacity or large starting torque to improve starting performance.

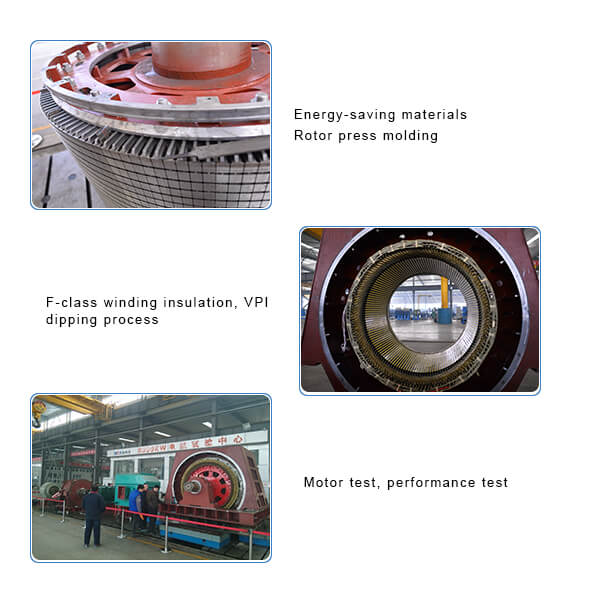

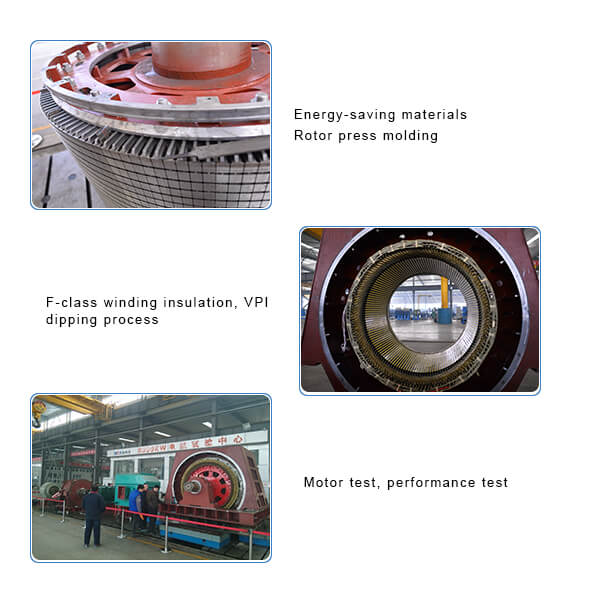

YR series heavy duty high voltage slip ring motor (open type) adopts Class F insulation grade. The rotor coil is made of copper strips wrapped with Class F insulation material, and the welding between the coils and between the coil and the conductive row is made of silver brazing to ensure the reliability of the motor operation.

YR series large high voltage slip ring motor (open type) is generally made of single shaft extension, which can be made into double shaft extension according to user needs. The direction of motor rotation can be arbitrarily selected, but it cannot be reciprocated or reversely braked.

YR series heavy-duty high-voltage slip ring motor (open type) is a wound rotor three-phase asynchronous motor. This type of motor complies with international ISO standards. The motor cooling method is IC01, and the motor is installed in IMB3 (horizontal with foot). The rated frequency is 50HZ and the rated voltage is 6KV, 10KV.

YR series heavy-duty high-voltage slip ring motor (open type) is suitable for use in environments where the altitude does not exceed 1000M and the ambient cooling air temperature does not exceed 40°C. We are also willing to manufacture products for special environments and conditions according to the needs of users.

This series of motors is a steel plate welding machine base with protection class IP00. It is compact in structure and self-recognized for ventilation and cooling. It is designed to be IP44 pipeline ventilation according to user needs.

YR series heavy-duty high-voltage slip ring motor (open type) stator windings are drawn down by VPI vacuum pressure, and the motor has good insulation and moisture resistance. The rotor winding coil is F-class. The bearing is a seat type sliding bearing, the lubrication method is compound lubrication, and the self-lubrication can be adopted in low power and in low temperature environment.

YR series heavy-duty high-voltage slip ring motor (open type) can be equipped with stator winding temperature measuring device and bearing temperature measuring device, which can realize real-time monitoring and alarm of long-distance temperature. This series of motors can be used to drive various grinding machines and lifting machines. , winch rolling mill, crusher, fan, pump and other machinery.

Product Parameters

Stator core outer diameter range: 1180-2150mm

Power range: 400KW-5000KW

Number of poles: 6/8/10/12

Voltage: 6KV/6.6KV/10KV/11KV

Rated frequency: 50HZ/60HZ

Protection level: IP00/IP21

Cooling method: IC01

Insulation class: F

Working system: S1

Stator connection; Y

The application temperature of the motor is not more than 1000m; the ambient temperature is not lower than 40°C, there is less dust, no indoor environment such as steam, acid, alkali and other corrosive and explosive gases; the allowable voltage deviation range is ±5%.

Feature of Product

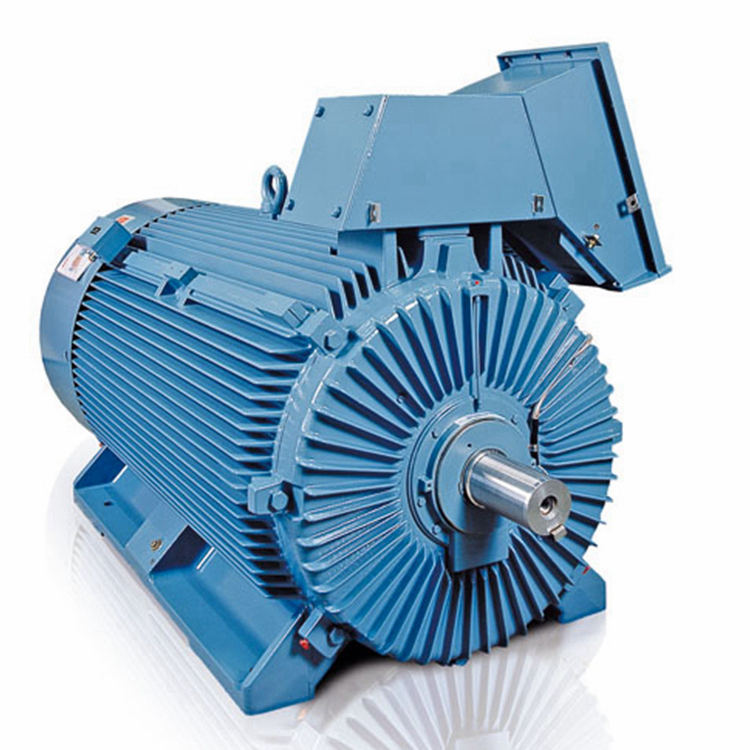

YR series heavy-duty high-voltage slip ring motor has large starting torque and strong overload capability. It has the advantages of high efficiency, low noise, small vibration, reliable structure and beautiful appearance.

Equipment Capacity

The company has large-scale laboratory, intelligent CNC winding machine, CNC rising machine, automatic wrapping machine, VPI high pressure vacuum immersion system, large-scale dipping paint drying furnace, 60 tons test platform, large vertical car, milling machine, grinding machine, Each type of dynamic balancing machine, double-feedback test and detection system with 6MW (12MW) motor and other motor production professional equipment more than 500 sets, sound mechanical equipment processing capacity, to lay a good foundation for customers to improve good quality motor products.

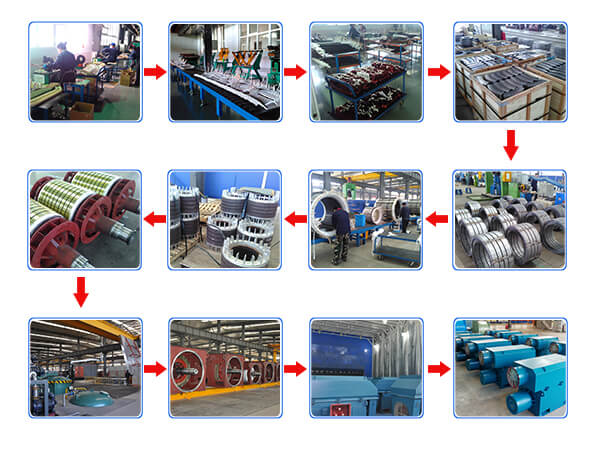

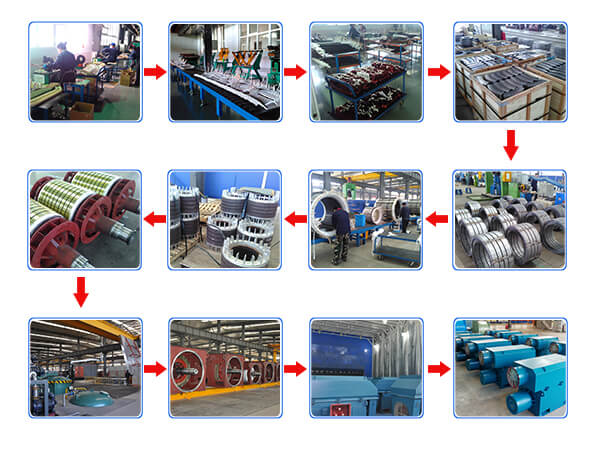

Main Process Flow of the Motor

Motor stator: casing processing → punching press → iron core seating → coil making → weaving → dipping paint drying

Electronic rotor: blank shaft processing → iron core press installation → iron core cast aluminum → rotor string shaft → weave → dipping paint drying → dynamic balance

Motor assembly: stator rotor assembly → machine test → motor appearance coloring → packaging storage

Product Use

The motor products manufactured and sold by our company are used in many industries, such as electric power, mining, steel metallurgy, petrochemical, water conservancy, transportation, building materials and many other industries. The equipment for the motor is pump, machine tool, fan, mill, crusher, rolling mill, compressor and many other industrial equipment.

About Us

Shijiazhuang ZCL Electric Motor Technology Co., Ltd. is a company mainly engaged in the manufacture, research and development and sales of motor products. The company has many types of motor products, including IEC standard motors. It is a professional IEC motor manufacturer. Related motor products have passed the product certification in China, the United States, Canada, Europe, the Middle East and other regions, and the products are exported to all over the world. Companies adhere to the "focus on products, service" business philosophy, is committed to improving the quality of safe motor products and services for customers around the world.

Why Choose Us(our service advantage)

1. Professional motor manufacturing service provider;

2. Sound product quality management and certification system;

3. Have a professional sales and technical service team;

4. The motor has perfect process and strong mechanical processing capability;

5. High standard product technical service system;

6. Good faith and mutual benefit, good credit guarantee.